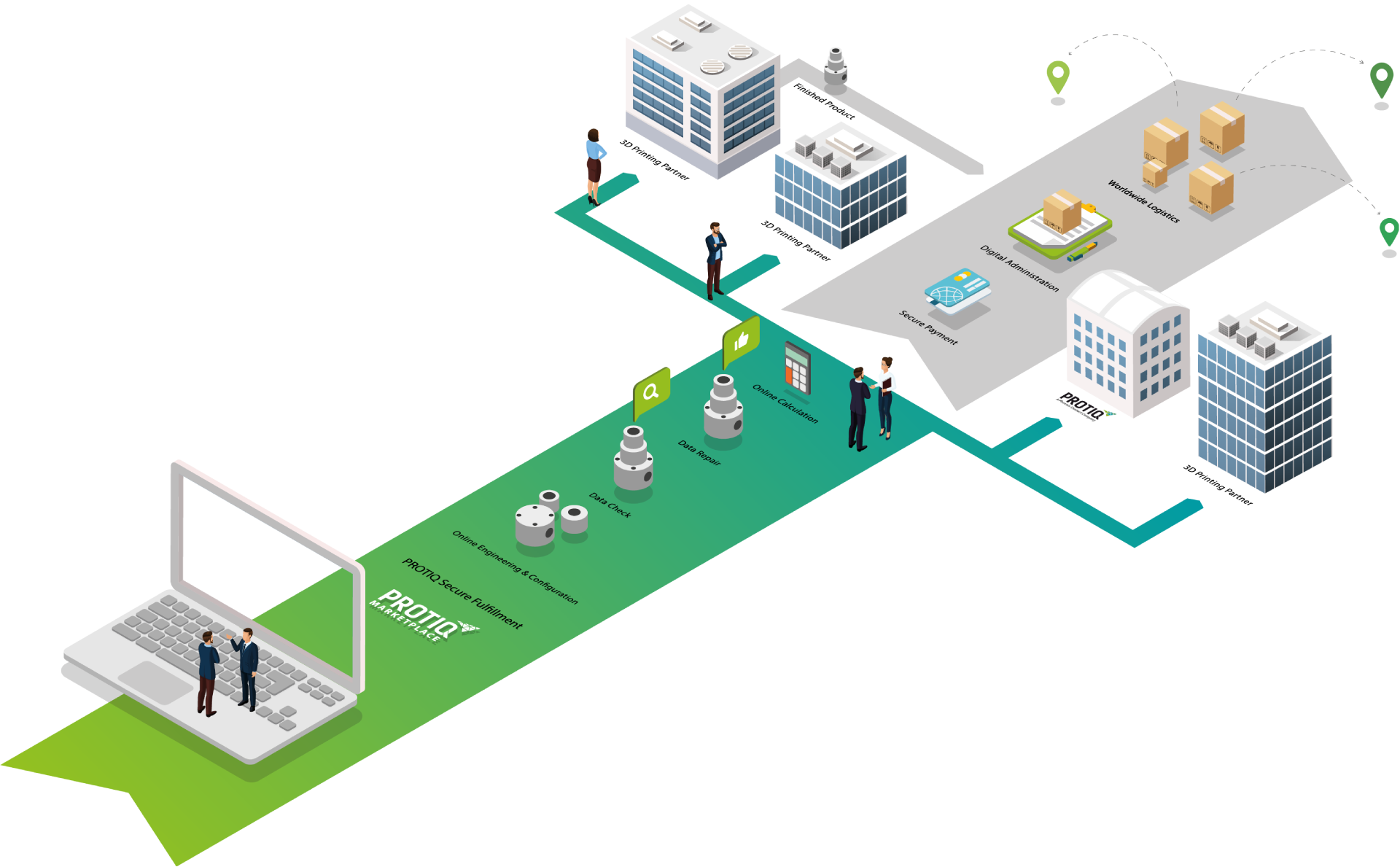

Welcome to the PROTIQ Marketplace

In the marketplace for industrial 3D printing, you can quickly and easily select several 3D printing providers at once from the services offered. With exceptional expertise in a wide range of additive manufacturing disciplines, we can fulfill each and every customer request.

All 3D printing processes on one portal

Got a specific idea, but don’t know what manufacturing process would be the best to implement it? In the PROTIQ Marketplace, you’ll find a wide range of 3D printing processes to choose from. We’ll tell you the specifics for each production process and the properties of the end products.

3D printing for every requirement

In collaboration with our partners, we are setting new standards in order processing flexibility: As a result, we can offer both customized piece production as well as the production of larger product series for a wide variety of industries. Choose from a wide range of services and take advantage of the multitude of configuration options for designing your 3D object.

The world of 3D printing continues to grow

Over the last few years, what was once the niche technology of 3D printing has evolved into a cross-industry innovation driver that is in ever-greater demand. Today, 3D-printed objects are used in the automotive, aviation, and aerospace industries, as well as in medical engineering, for example.

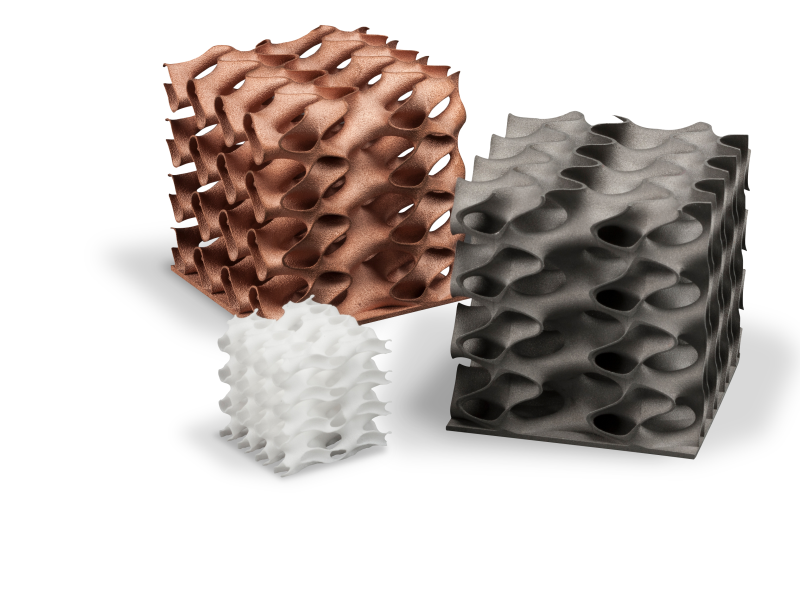

New design freedom, thanks to additive manufacturing

Many components that were once produced using complex manufacturing processes, such as milling, drilling, and turning, can now be made with a 3D printer – additive manufacturing offers some major benefits: The layered structure of a component allows for complex geometries to be realized and internal functions to be integrated. Product development no longer needs to be oriented toward production methods, but instead can focus fully on the functionality of the end product.

Innovation driver 3D printing

The design-driven construction process in additive manufacturing has already produced a wealth of remarkable innovations, such as the use of highly conductive copper for the production of geometrically optimized inductors – one of the latest developments from PROTIQ.

Deutsch

Deutsch English

English Italiano

Italiano