FAQ

What is 3D printing?

What is additive manufacturing or 3D printing:

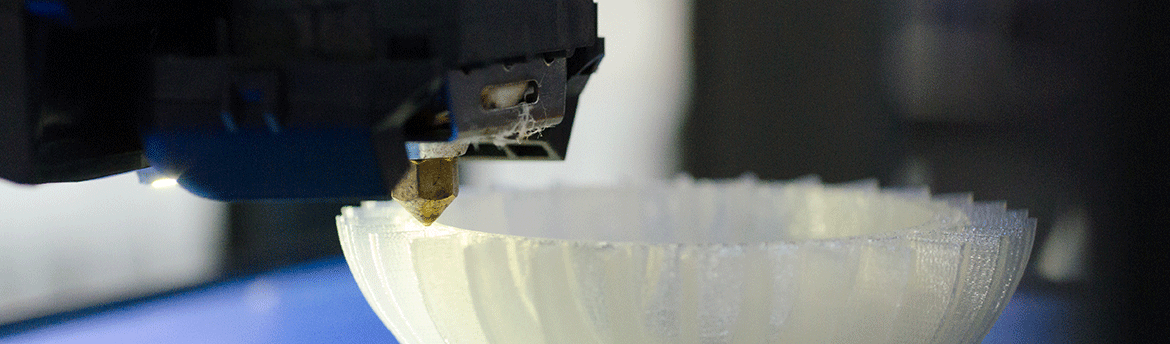

From a technical point of view, the term Additive Manufacturing (or generative manufacturing) summarizes several processes that produce components directly from 3D data. In practice, additive manufacturing equals a revolution.

- It offers great freedom

The different methods can be used to produce products that were previously impossible – or merely difficult – to realize. Especially when it comes to the implementation of complex internal structures, additive manufacturing processes are far superior to other technologies. The same applies to alloys. Thanks to additive manufacturing, metallic materials can now be combined to overcome the limits of conventional processes. - It promotes innovation

Many of the objects we use today have become possible only through additive manufacturing. New materials are coming to the market every day. PROTIQ has made its first contribution here with high conductivity copper. With new materials and processes, objects will be created in the future and fields of application opened up that are not yet conceivable today.

- It shortens production and logistics processes

With generative manufacturing processes, the gap between development and the first use of a product is considerably shortened. The reason for this lies in the elimination of several production steps. What was previously produced in lengthy successive processes, sometimes using different systems, is now, in the best case, produced within a single work step. And all on one machine.

You will find out how what an additive manufacturing process looks like in detail in the videos on our production processes. To get started in additive manufacturing, we offer both basic and advanced training tailored to your needs.

3D-Production

What processes do you use for manufacturing?

We basically use four production methods:

- Laser sintering

- Stereolithography

- PolyJet/MultiJet

- Selective laser melting for metals

Read more about the 3D printing process used at the PROTIQ Marketplace here.

Are there size limitations for objects to be printed?

Yes there are. The manufacturable size depends on the method used. The PROTIQ Marketplace software automatically checks your data. It will be indicated if the object is too large or too small for the procedure. You then have the option to change both the size of the object and the method or material.

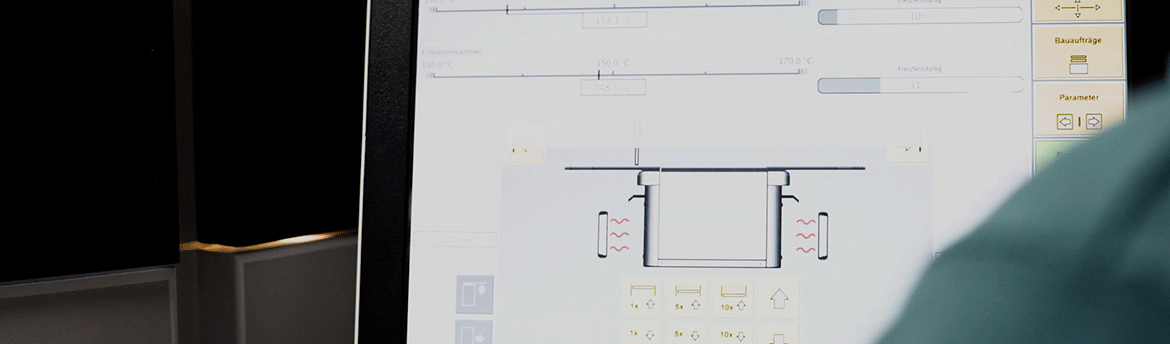

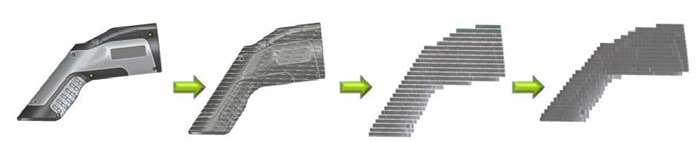

What is the stepped layer effect?

Production in additive manufacturing is usually characterized by a layered structure. Depending on the system resolution, layer thickness, and construction direction, an effect similar to the steps of a staircase may occur.

Is there a limit to the number of pieces?

There is no limit in order quantity.

How thick must an object be before it is solid?

How thin or thick the wall of a 3D object may or must be depends on the material and the method and is automatically checked by the PROTIQ Marketplace. If an item is not printable, it will be indicated. You can then decide whether you still want to print the object with the current specifications regardless.

What types of objects have you printed so far? Are there examples of your work?

The PROTIQ Marketplace team has been working for many years for the various divisions of the Phoenix Contact Group and other companies. We are happy to present sample objects in a personal consultation.

Can I get movable elements produced?

Yes. Depending on the complexity, we produce moving 3D components in one printing process. If this is not possible due to size or other factors, we are happy to offer you our model building service or our professional consultation.

Can I manufacture series production components?

Yes. The basic requirement is that the materials you choose meet your requirements.

What does your quality control consist of?

The PROTIQ Marketplace performs an automatic quality control of the data before production. Our proven test software handles small fixes independently. For major repairs, you will be notified of the changes made and you can give your consent to production before your item will be manufactured. After production, all objects undergo quality control. In addition, the precision of the systems is ensured by regular quality measurements.

3D material / texture

What materials do you offer?

We offer the following materials:

Metal:

- Tool steel (MS1 - 1.2709)

- Stainless steel (PH1 - 1.4540)

- Stainless steel (1.4542)

- Stainless steel (1.4404)

- Aluminum (AlSi9Cu3)

- Aluminum (AlSi10Mg)

- Inconel (IN625)

- Inconel (IN718)

- CobaltChrome (CoCrW)

- Copper (RS-copper)

- Copper (CuNi2SiCr)

Plastic selective laser sintering:

- PA11 (PA1101)

- PA12 (PA2200)

- PA12 - glass ball filled (PA3200GF)

- PA12 - aluminum filled (Alumide)

- PA12 - natural (PrimePart PLUS 2221)

- PA12 - flame-retardant (PA2241 FR)

- TPU (TPU X92A-1)

- PEK (PEEK HP3)

Plastic PolyJet/MultiJet modeling:

- VeroClear

- VeroWhite+

- Digital ABS

- DM 9840

- DM 9850

- DM 9860

- DM 9870

- DM 9885

- DM 9895

- TangoBlack+

Plastic stereolithography:

- VisiJet Tough

- VisiJet Clear

- VisiJet HiTemp

Ceramics:

- Aluminum Oxide (Al2O3)

- Zirconia (ZRO2)

- Tricalcium Phosphate (TCP)

More information about our materials can be found here.

What is the minimum spacing between moving parts to ensure that they will be able move?

This depends on the object’s geometry: As a rule, 0.8 mm of spacing is enough. 0.6 mm can also sometimes be implemented for small and easily accessible places.

Can I produce components with different materials or multi-material components?

Yes. To produce multi-material components the PROTIQ team combines different materials and thus meets complex requirements. You can set the level of hardness for your objects, from rubber-elastic to hard. In this way, the multi-component parts can have different properties yet still be created in one printing step.

3D programs

What is a CAD program?

Computer-Aided Design (CAD for short) refers to computer-aided design or modeling. The term CAD covers all programs in which digital models can be created in 2D or 3D. Modeling in a CAD program optimizes the entire development process of a product. Even before a prototype is produced, simulations and calculations can be carried out with which the behavior of the component can be assessed under realistic conditions. Improvements and changes can be transferred to the 3D model with no loss of time and, thanks to comprehensive documentation options, also be reproduced in late development phases. Software vendors often develop their own programs or extensions for different industries that meet the respective design and documentation requirements.

What 3D print program is suitable for beginners?

There are many programs for 3D printing beginners that dispense with complicated functions and are limited to modeling the 3D object. Many of these beginner-friendly programs are based on the sculptor principle, which allows a particularly intuitive operation. First, a simple basic shape is selected, for example a sphere or a cuboid. More details are gradually added to the object on further levels. A popular example of a free program that uses this method is Sculptris from software developer Pixologic. Another interesting program for 3D newcomers is SculptGL. This is a browser-based application in which 3D models can be shaped with simple tools using a mouse or a touch pen.

Creating a 3D file

How can I create an appropriate file to print at protiq?

The partners of the PROTIQ Marketplace can generally work with all common 3D file formats. This means you can use any software to make your 3D file. Of course, we also print files that you have not created yourself – for example, from freely available and Creative Commons licensed or purchased files. These file formats can be processed by PROTIQ:

STL, OBJ, 3DM, 3DS, ACIS, VRML, ZPR, PLY, DXF, AMF, Sketch-Up, CATIA V4, CATIA V5, IGES, VDA, ProE, UG / Parasolid, STEP, ACIS SAT, Solidworks, JT, VDA, FBX, Collada

We will calculate a price for you online immediately for these file formats. Further formats are possible on request.

What must I pay attention to in building stl files?

Please note the following information regarding faceting when creating STL files: The maximum distance between the triangles, the nominal contour, and the maximum angle with the nominal contour can be provided as specifications. The distance should be max. 0.01 mm, the angle max. 5°.

In addition, we fix these areas automatically for STL files:

-

Media density

All surfaces in the component must form a closed volume without holes in the surface. If this is not the case, PROTIQ automatically repairs it. -

Inverted normal values

For STL files, the surface is defined by triangles. The triangles have a vector that indicates whether it represents an external or interior side. When these vectors or normal values are mixed up, it is no longer clear where material can be printed. This is also corrected independently by the PROTIQ Marketplace.

Do you also offer help with the creation of a suitable file?

In a word, Yes. Our teams have years of experience in the entire additive manufacturing sector and provide detailed advice to their customers on various aspects of 3D printing and reverse engineering. Just contact us, we are happy to help.

Which file formats can be processed by the protiq marketplace?

We will immediately calculate a price online for you for these formats:

STL, OBJ, 3DM, 3DS, ACIS, VRML, ZPR, PLY, DXF, AMF, Sketch-Up, CATIA V4, CATIA V5, IGES, VDA, ProE, UG / Parasolid, STEP, ACIS SAT, Solidworks, JT, VDA, FBX, Collada

Further formats are possible on request.

Is there a maximum size for uploading files?

The file should not exceed 50 MB in size. For larger files, we will gladly provide you with a secure FTP server on request.

How can various file formats be converted to be used for the protiq marketplace?

It is best to export your file to a format that we can process. If this is not possible, you can use a converter. There are some free programs that serve this purpose.

Can I upload assemblies?

Yes. Please provide us with all necessary CAD data.

3D service

Your website is optimized for industrial requirements? What does that mean?

All the functions of the PROTIQ Marketplace, from configuration to payment, were developed on the basis of many years of experience with customers in the industrial environment. For example, you can save several shopping carts as projects in your account. In addition, several users with different access rights can be created for smooth teamwork (ordering, creating shopping carts, expanding shopping carts, deleting items from shopping carts).

In the area of configuration we facilitate your work with a comfortable module upload, for example. A wide range of payment methods completes our service for business customers. We also host your information on our own servers to provide you with the highest level of security.

How can I contact you?

The PROTIQ Marketplace service team is always available for you! You can call us, write an email or be conveniently called back by us.

Order / shipping

How fast do you ship? When can I expect to receive my 3D object?

For orders within Germany, your 3D object usually arrives one to two business days after completion. Of course you can also use our express delivery. In exceptional cases the delivery time can be 2-10 working days. Read more about our shipping terms here.

What payment methods do you accept?

We accept the following payment methods:

- Debit

- Payment in advance

- Purchase on invoice

- Credit card

- PayPal

Deutsch

Deutsch English

English Italiano

Italiano