3D-printed spare parts

If a technical component fails and the original part is no longer available - or only with a considerable delay - industrial 3D printing offers an efficient and flexible alternative. Additive manufacturing allows spare parts to be produced precisely, in line with demand and often significantly faster than with conventional processes.If original parts are missing, PROTIQ supplies the solution - quickly, precisely and individually manufactured.

Maintaining and repairing technical devices, machines or vehicles is often a major challenge - especially when suitable spare parts are no longer available or are only offered at high prices. With older models in particular, there is a great desire to preserve the originality and replace components as authentically as possible. But what can you do if the market no longer offers suitable parts?

This is where additive manufacturing - better known as 3D printing - offers an innovative solution. It makes it possible to produce spare parts quickly, precisely and cost-effectively, even if the original is no longer in production. Instead of long waiting times or time-consuming research, the required components can be manufactured directly from digital data.

This data is either created using a 3D scan of the original part or designed using CAD software. This allows not only faithful reproductions to be created, but also individual adjustments to be made - for example to optimize function, accuracy of fit or design.

Whether it's mechanical components, interior details or complex housing parts: Additive manufacturing opens up new possibilities for producing spare parts flexibly and in line with demand - regardless of series production or stock levels.

Areas of application and examples

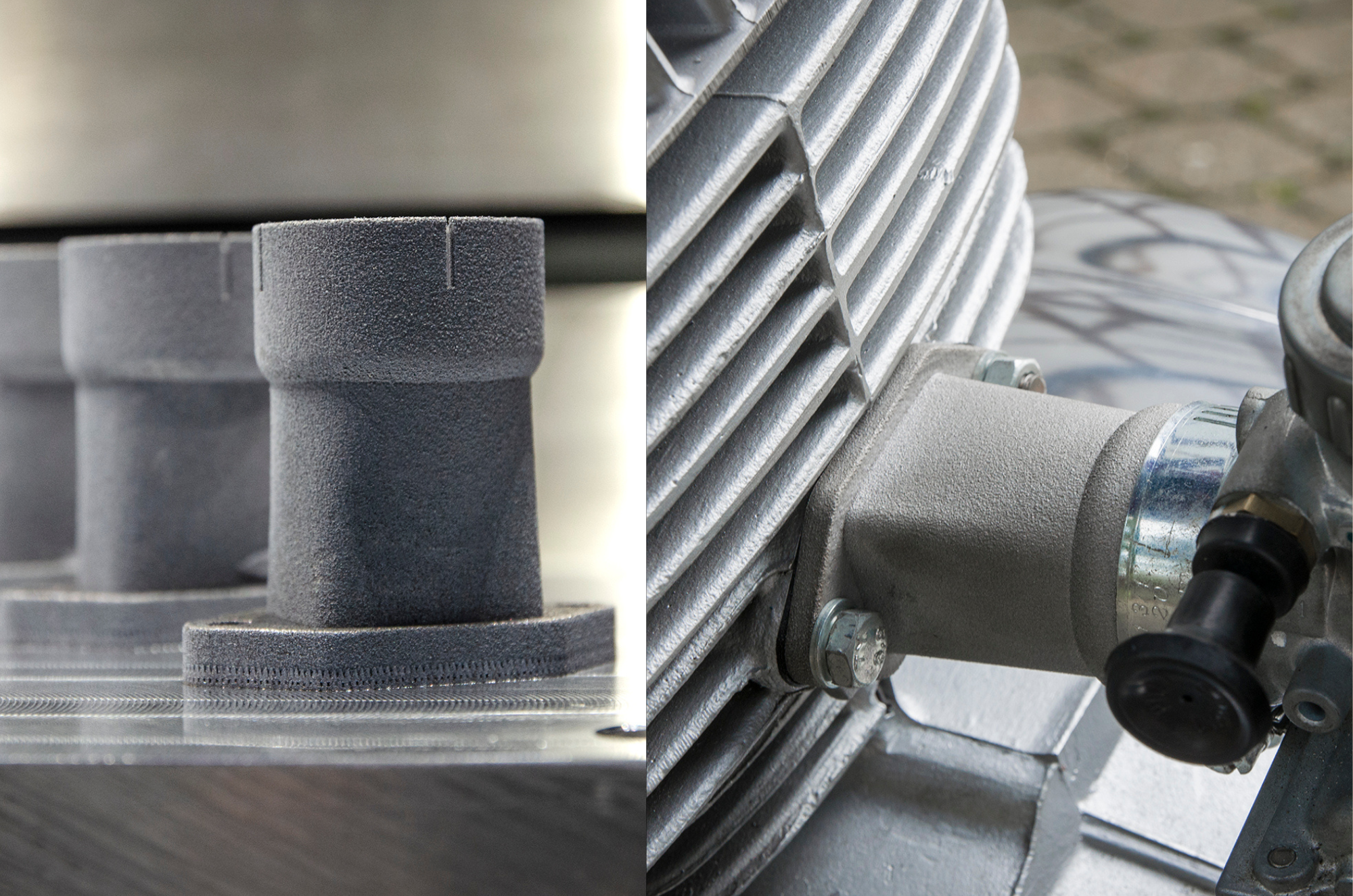

Industry

In industrial applications, the availability of spare parts is crucial for operational safety and productivity. The procurement of original components can be difficult or time-consuming, especially for older machines or special systems. 3D printing offers a flexible and economical solution here: fast, precise and individually manufactured.

- Seals and spacers

- Brackets and adapters

- Housing parts and covers

- Connecting elements

- Guide rails and rollers

- Gear wheels and bearing housings

Vehicles

In the vehicle sector, whether for modern models or classic cars, spare parts are often difficult to obtain or involve long delivery times. Additive manufacturing enables the rapid post-production of precisely fitting components, even in small quantities or as one-offs.

- Radiator figures/emblem replicas

- Interior parts and panels

- Housing and covers

- Connecting elements

- Air and exhaust components

- Fasteners for lighting and accessories

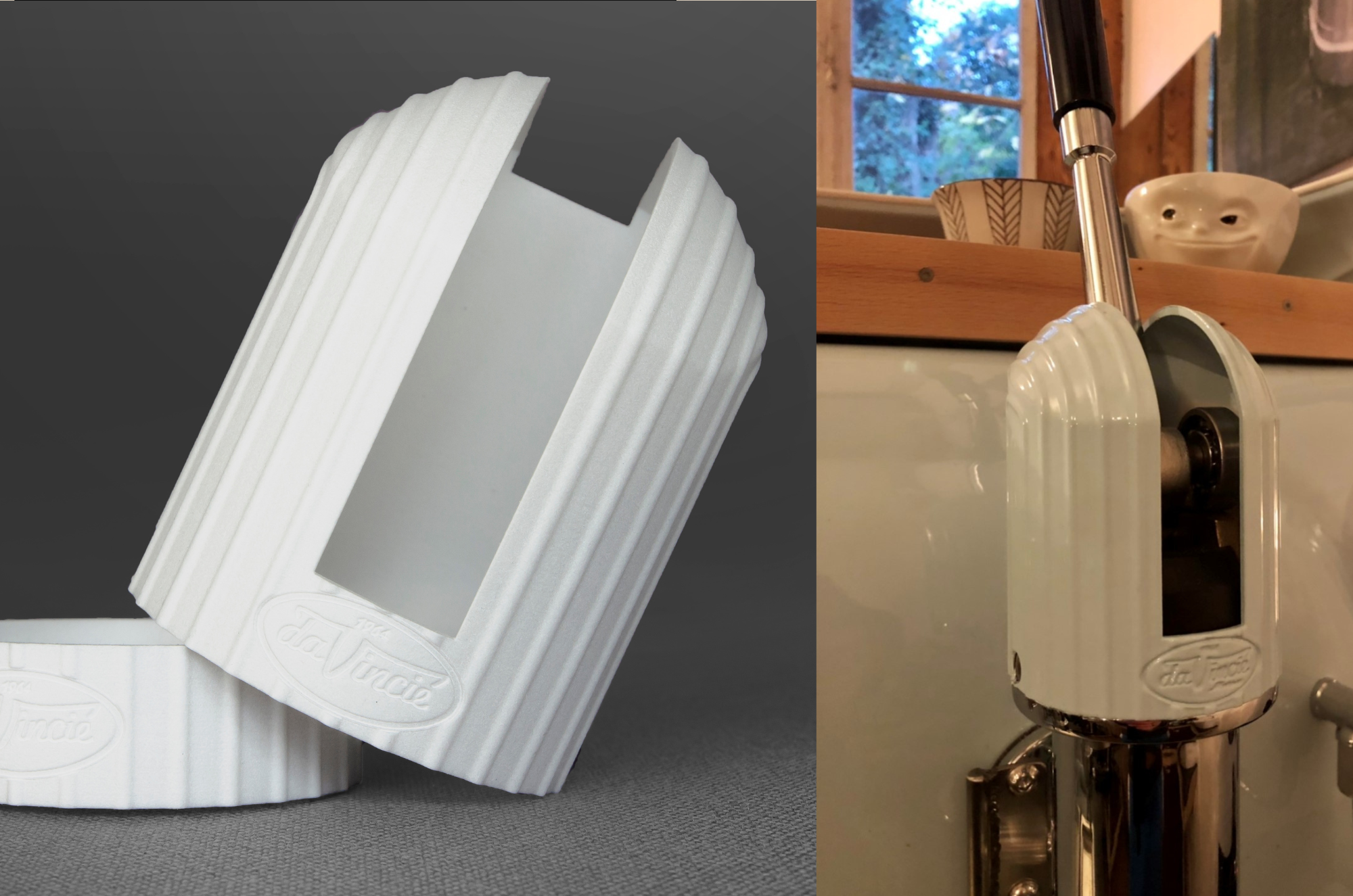

Household & everyday life

3D printing also offers a practical alternative to traditional spare parts procurement in the private sphere. Defective or lost parts for household appliances, furniture or garden equipment can be easily reproduced - often even more robust or functional than the original.

- Handles and knobs

- Brackets and clips

- Housing parts

- Covers and panels

- Connecting elements

- Spare parts for household appliances

Gear wheels

Gears are essential components in many technical applications - whether in machines, vehicles or appliances. Their shapes and properties are diverse: size, tooth profile, material and alignment vary depending on the area of application. Especially with older systems or special solutions, suitable replacement gears are often no longer available or difficult to reorder.

-

This is where PROTIQ's gear configurator offers a practical solution: with just a few clicks, gears can be individually configured to size and released directly for production in 3D printing. This is particularly helpful when original parts are no longer available or there are special requirements.

Thanks to rapid manufacturing - fast and flexible production using additive manufacturing - production is already worthwhile from a quantity of 1. No special tools are required, as is the case with injection molding, for example, which saves time and money. The gears are manufactured directly from digital CAD data and can be produced and delivered within just a few days.

The result is an economically viable solution for the supply of spare parts - customized, fast and a perfect fit.

From object to print: how 3D models for spare parts are created

In order to have a component manufactured using 3D printing, a digital 3D model is first required. One way to create this is to design it in a CAD program. However, these programs are often complex and require technical expertise, which makes it difficult for non-experts to get started.

Access is easier with user-friendly software solutions that rely on the so-called sculptor principle: The desired object is intuitively modeled from a basic shape and details are added step by step.

Alternatively, existing components can be precisely digitized using 3D scanning technologies - even if design data is no longer available. This creates precise replicas that can be used directly for printing.

Before a model is produced, the file must be checked for printability. This includes a closed surface without holes and sufficient wall thickness. The required stability depends on the material used, the printing process and the planned application.

General design recommendations

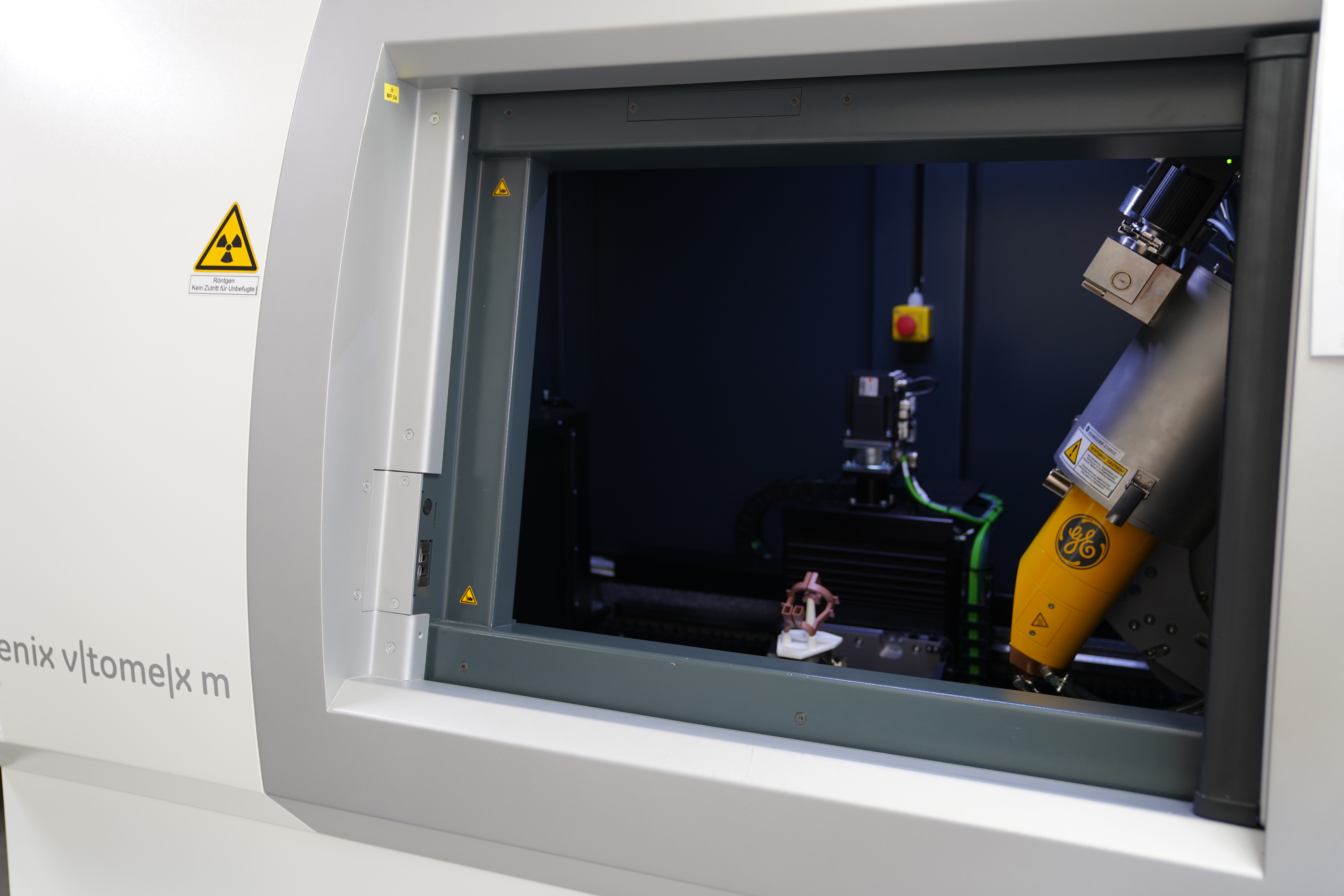

Digitizing spare parts - precise 3D data through computer tomography

Computed tomography (CT) offers an effective way of generating high-quality 3D data, particularly for spare parts that are difficult to obtain or are no longer produced. The component is positioned on a turntable in a CT scanner and X-rayed from various angles. A precise, three-dimensional model is created from the numerous individual images using a reconstruction process.

This method is particularly suitable for complex or internal structures where conventional measuring methods reach their limits. Dimensional deviations, defects or geometric details can be reliably recorded - ideal for the reproduction of spare parts in 3D printing.

No CAD data available?

Even if no CAD data is available, replacement components can be digitized in this way and prepared for additive manufacturing. The prerequisite for this is that the object consists of a homogeneous material. If this is not the case, the CT evaluation cannot guarantee a clear separation of the materials, which makes model generation difficult or impossible.

We create the appropriate CT scan data for you.

Variety of materials for functional and durable spare parts

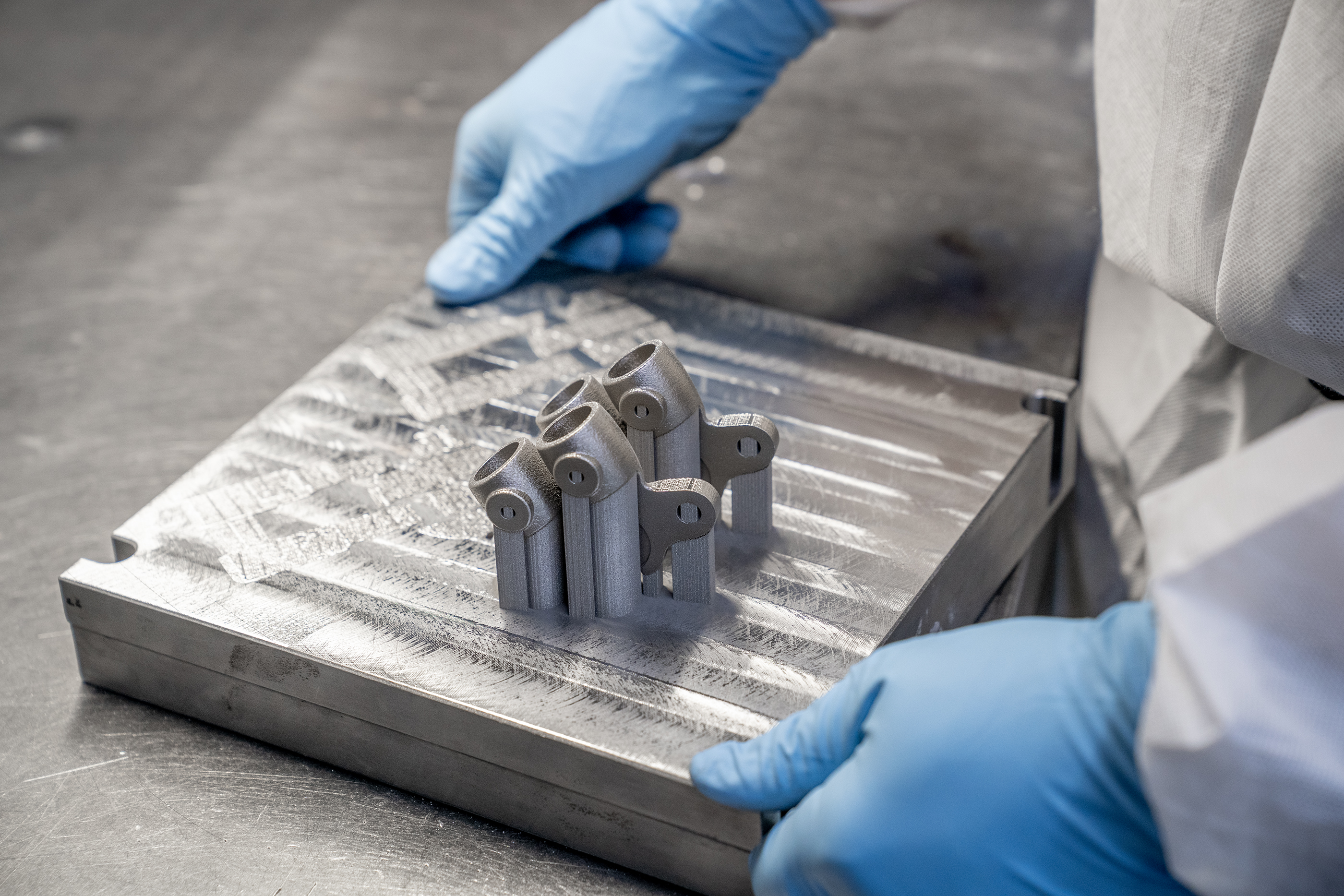

Components manufactured using selective laser sintering (SLS) for plastics or selective laser melting (SLM) for metals are particularly suitable for the production of functional spare parts using 3D printing. Both processes produce high-precision, resilient components by melting fine powder in layers using a laser and joining it to form a solid component.

The resulting parts are characterized by high mechanical stability and durability - ideal for industrial use or demanding everyday applications. Plastic parts can be subsequently dyed or painted, while metal components can be further refined using processes such as vibratory grinding, polishing or coating.

In addition to traditional plastics and metals, special materials such as glass, ceramics or rubber-like materials can also be processed. This opens up a wide range of possibilities for functional, temperature-resistant or flexible spare parts, precisely tailored to the respective application.

More information here:

Making spare parts permanently available

Additive manufacturing not only offers new possibilities in production, but also in digital spare parts logistics. By creating a digital twin, i.e. a complete three-dimensional model of a component, spare parts can be permanently secured: independent of physical stocks or supply chains.

Companies can digitally archive critical components and re-produce them at any time if required. It is possible to manufacture the component in different materials or variants, depending on the area of application or technical requirements. This reduces storage costs, increases security of supply and makes in-house production sustainable in the long term.

A digital twin not only replaces the physical spare parts warehouse, but also creates the basis for a flexible, scalable and resilient spare parts strategy. Investing in the digitalization of your components today ensures availability tomorrow - even for machines and systems that are no longer in production.

Deutsch

Deutsch English

English Italiano

Italiano