Steel in 3D printing: high-strength solutions for industrial applications

Tradition meets technology

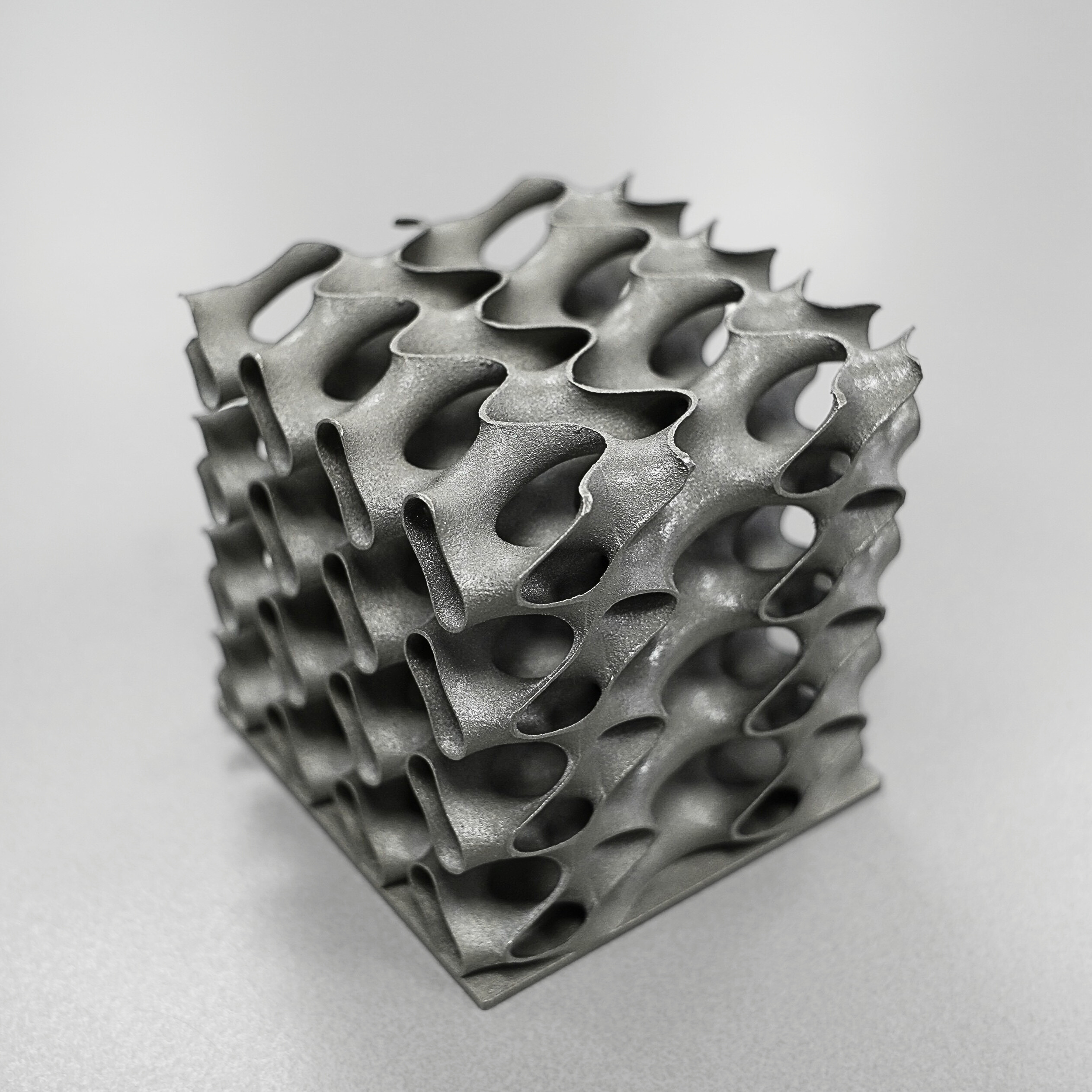

Steel and stainless steel are among the most important materials in industrial production. Their high strength, temperature resistance and corrosion resistance make them indispensable for demanding applications. Thanks to the use of modern 3D printing processes, steel and stainless steel components can now be produced efficiently, precisely and with complex geometries - ideal for prototypes, functional parts and series components.

Steel is one of the oldest and most versatile materials in industrial history. Since its systematic production in the 19th century, it has shaped machine building, architecture and mobility worldwide. With the development of 3D printing, steel is experiencing a new era: it is no longer just cast or forged, but also built up layer by layer - precisely, efficiently and geometrically free.

Thanks to modern processes such as selective laser melting (SLM), high-strength components made of stainless steel alloys can now be produced directly from digital data. These materials not only offer excellent mechanical properties, but also corrosion resistance and temperature resistance - ideal for demanding industrial applications.

Steel in additive manufacturing

From powder to component

Additive manufacturing with steel is based on selective laser melting (SLM), a high-precision process in which metallic powder is melted layer by layer to form a solid component. The process begins with a specially prepared steel powder, which is applied to the building platform in a thin layer.

A powerful laser beam scans the contours of the component and melts the powder locally. After solidification, a solid metal layer is created. This process is repeated layer by layer until the complete component is built up - directly from the digital CAD data, without molds or tools.

After the SLM printing process, the post-processing of the steel component begins. First, the support structures that were necessary for stabilization during printing are removed. This is followed by heat treatment to relieve stresses and achieve the desired mechanical properties. The surface is finished by looping, blasting or polishing, depending on the requirements. For precise fits or technical functions, the component can also be mechanically reworked, for example by milling or drilling. This transforms the raw part into a fully functional, resilient and ready-to-use product.

Advantages of steel in selective laser melting

- Hardenability and reworkability

- Good dimensional accuracy and attention to detail

- Variety of materials for different requirements

- Design freedom

Areas of application

Machine and tool shop

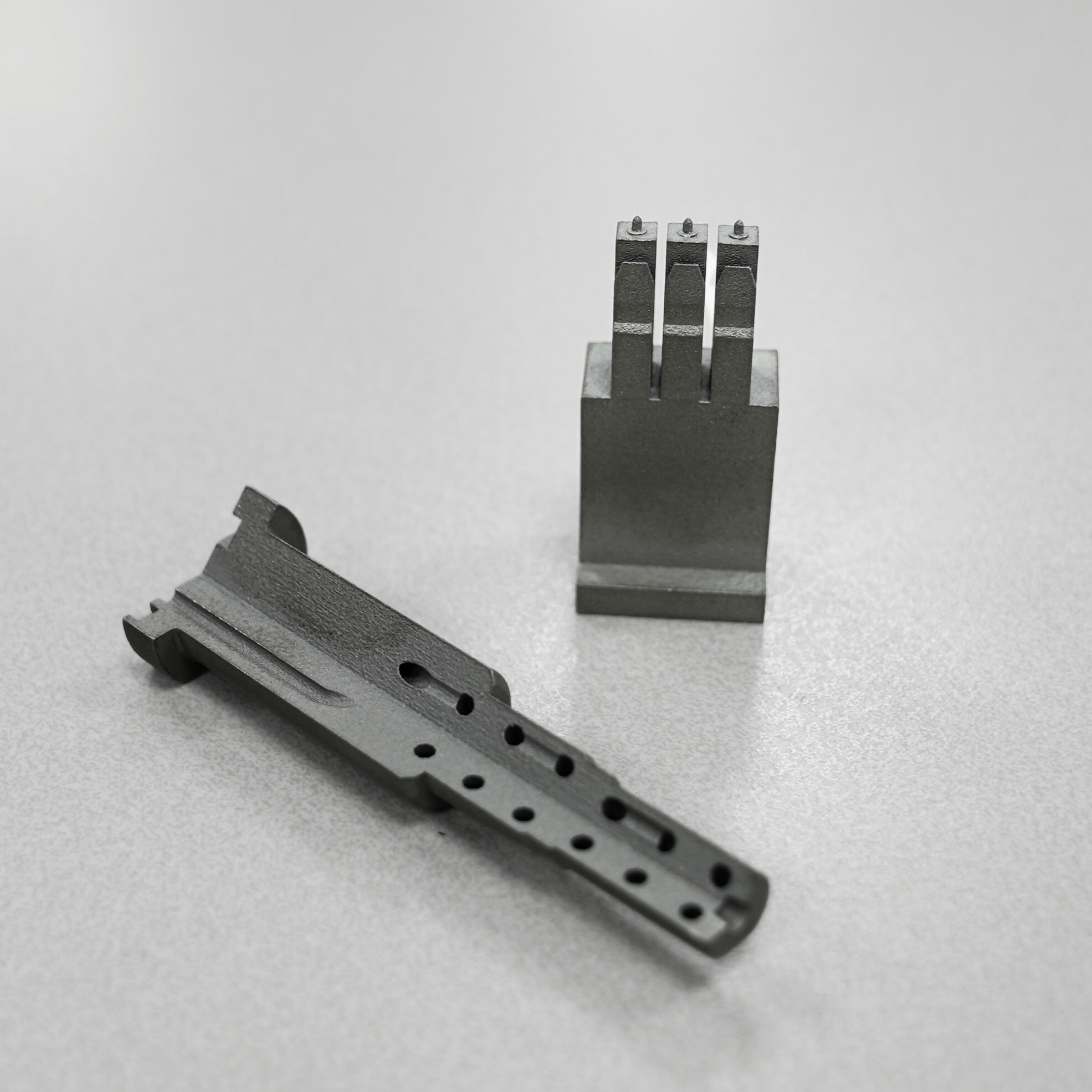

In machine building, steel and stainless steel components from 3D printing are used for highly stressed functional parts, brackets, connecting elements and complex geometries. Tool steels such as MS1 (1.2709) and H11 (1.2343) are particularly suitable for mold making as they offer high hardness, wear resistance and temperature resistance. Companies benefit from short development cycles and the ability to manufacture tools directly from CAD data - without complex milling or casting processes.

Chemical and food technology

Corrosion-resistant stainless steels such as 1.4125 or 316L are essential in these industries, as components regularly come into contact with aggressive media or cleaning processes. Printed components such as nozzles, valves, brackets or housings must not only be functional, but also hygienic and durable. 3D printing offers the opportunity to create complex and easy-to-clean geometries without weld seams or dead spaces.

Automotive industry

Stainless steel alloys such as 1.4542 or 1.4404 are used in the automotive industry to produce components with high strength and corrosion resistance. Typical applications include chassis components, brackets, sensor housings or thermally stressed parts in the engine compartment. 3D printing enables the rapid production of prototypes, small batches or spare parts.

Our steel materials

Aluminium (AlMgSi0,5)

Characteristics

Specials: very anodizable

Decorative anodizing quality: Very good

Hard anodizing: Very good

Weather resistance: Very good

Resistance to seawater: Good

Uses: metal construction, textile industry and household articles

Process: laser melting (metal)

| Base color | Light gray |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | rough, lightweight |

Aluminum (AlSi10Mg)

Characteristics

Uses: functional components and small parts with high strength and low weight

Process: laser melting (metal)

| Base color | Light gray |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | rough, lightweight |

Aluminum (AlSi9Cu3)

Characteristics

Uses: engines and transmissions (good high-temperature strength)

Process: laser melting (metal)

| Base color | Light gray |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | rough, lightweight |

Brass (RS-Brass)

Characteristics

Uses: Components with high corrosion resistance, jewellery with golden shine

Process: laser melting (metal)

| Base color | |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | fine texture, solid, heavy |

Cobalt chrome (CoCrW)

Characteristics

Uses: medicine, functional components, high-temperature applications

Process: laser melting (metal)

| Base color | gray |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | brittle, solid, heavy |

Copper (CuNi2SiCr)

Characteristics

Uses: cooling inserts for injection molding tools, fasteners, fittings

Process: laser melting (metal)

| Base color | copper |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | fine texture/finely woven, solid, heavy |

Copper (RS-copper)

Characteristics

Uses: prototypes with high electrical conductivity such as conductive elements and inductors

Process: laser melting (metal)

| Base color | copper |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | fine texture/finely woven, solid, heavy |

Inconel (IN625)

Characteristics

Uses: Aerospace, Motor Sports, Industry

Process: laser melting (metal)

| Base color | gray |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | coarse texture, solid, heavy |

Inconel (IN718)

Characteristics

Uses: Aerospace, Motor Sports, Industry

Process: laser melting (metal)

| Base color | gray |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | coarse texture, solid, heavy |

Pure Copper (CU-ETP)

Characteristics

Uses: prototypes with high electrical conductivity such as conductive elements and inductors

Process: laser melting (metal)

Features:

- 100% IACS

- 100% density

- 58 MS/m

| Base color | copper |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | fine texture/finely woven, solid, heavy |

Stainless steel (1.4125)

Characteristics

THOR44 | 440C | X105CrMoV17 | S44004

High strength knife steel

Hardness: up to approx. 63 HRC

Process: laser melting (metal)

| Base color | gray |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | slightly rough, solid, heavy |

Stainless steel (1.4404)

Characteristics

Uses: rustproof functional components and small parts

Hardness: up to approx. 20 HRC

Process: laser melting (metal)

| Base color | gray |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | slightly rough, solid, heavy |

Stainless steel (1.4542)

Characteristics

Uses: rustproof functional components and small parts

Process: laser melting (metal)

| Base color | gray |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | slightly rough, solid, heavy |

Stainless Steel (CX)

Characteristics

Uses: moulding tools, medical and food industry

Hardness: up to approx. 50 HRC

Process: laser melting (metal)

| Base color | grey |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | slightly rough, solid, heavy |

Stainless steel (PH1 - 1.4540)

Characteristics

Uses: rustproof functional components and small parts / medicine, aerospace

Hardness: up to approx. 45 HRC

Process: laser melting (metal)

| Base color | gray |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | slightly rough, solid, heavy |

Steel 1.0980

Low-alloy steel S420

When processed by selective laser melting, a homogeneous microstructure forms without rolling texture or preferred direction. The microstructure becomes increasingly ferritic martensitic with very fine carbides. In contrast to cold-formed components, there is no work hardening in the printed components.

Process: laser melting (metal)

| Base color | Gray |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | robust, heavy |

Steel 1.8974

Low-alloy steel S700

The Rp700 is a micro-alloyed, thermo-mechanically rolled steel with high yield strength, which is widely used as sheet metal for cold forming. Its microstructure is low in pearlite, ferritic with fine carbides (and isolated titanium carbonitrides). Bainite is permissible as a second phase.

Process: laser melting (metal)

| Base color | Gray |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | robust, heavy |

Titanium Gr. 23 (Ti6Al4V – 3.7165 ELI)

Characteristics

Uses: Mechanical Engineering, Medicine and Motor Sports

Hardness: up to approx. 37 HRC

Process: laser melting (metal)

| Base color | gray |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | mat, rough, lightweight |

Titanium Gr. 5 (Ti6Al4V – 3.7164)

Characteristics

Uses: Aerospace, Medicine and Motor Sports

Hardness: up to approx. 40 HRC

Process: laser melting (metal)

| Base color | grey |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | mat, rough, lightweight |

Tool steel (H11 - 1.2343)

Characteristics

Uses: Inserts for injection moulding and die-casting tools with near-contour temperature control channels and complex geometries, functional components with integrated internal fluid lines

Hardness: after heat treatment up to approx. 54 HRC

Process: laser melting (metal)

| Base color | gray |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | robust, heavy |

Tool steel (MS1 - 1.2709)

Characteristics

Uses: injection molding inserts, springs and functional components

Hardness: up to approx. 52 HRC

Process: laser melting (metal)

| Base color | gray |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | smooth, solid, heavy |

Zink (Zamak 5)

Characteristics

Uses: Functional prototypes for zinc die-cast components from series material

Process: laser melting (metal)

| Base color | Light gray |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | finely structured, glossy, metallic |

Did you already know?

Metal components can also be visually and mechanically upgraded.

For a high-quality surface, printed steel components are mechanically smoothed after the printing process: typically by looping, blasting or polishing, depending on the desired look and function. These processes not only improve the feel, but also the dimensional accuracy and corrosion resistance.

Metallic materials such as steel naturally appear in neutral shades such as gray or silver. In order to visually highlight prototypes, functional samples or demonstration models, metal components can be subsequently painted in almost any RAL color. This allows certain features to be specifically emphasized, components to be identified or the appearance to be adapted to individual requirements.

Depending on the geometry and requirements, threads can either be printed directly or subsequently cut. While co-printing is practical for larger threads and low loads, thread cutting is recommended for precise, heavy-duty connections.

Do you have an idea or a specific project? Talk to us! We will be happy to advise you.

Are the components ready for use immediately after printing?

Post-processing is usually necessary: Removal of support structures, heat treatment for stress reduction and mechanical processing for fits or surface quality.

Can individual designs or special shapes be realized?

Yes, absolutely. At PROTIQ, we focus on design freedom. You can upload your CAD data directly and configure individual solutions - entirely according to your requirements.

How does ordering via the PROTIQ Marketplace work?

It's simple: you upload your CAD file, select the material and process and receive a quote straight away. After approval, we start production - transparently, quickly and reliably.

Which CAD data formats are accepted?

We support common formats such as STEP, STL and others. Details can be found directly on the PROTIQ Marketplace or are available on request.

Are there minimum or maximum sizes for the components?

Yes, there are technical limits depending on the process and material. These are documented on our website - or you will receive an individual assessment after uploading your file.

Is 3D printing with steel economical for series production?

Yes, especially for complex geometries, small to medium quantities or frequent design changes, 3D printing with steel offers economic advantages over conventional processes.

Deutsch

Deutsch English

English