Aluminum in 3D Printing: Lightweight Metal with Potential

Aluminum is one of the most important materials in modern industrial manufacturing. As a lightweight, mechanically robust, and highly versatile metal, it is ideally suited for lightweight construction. In additive manufacturing, aluminum offers additional advantages: high design freedom, short delivery times, and the ability to produce complex geometries efficiently.

A modern material with versatile properties

Aluminum (symbol: Al) is one of the most abundant metals in the Earth's crust and belongs to the group of lightweight metals. Its unique combination of physical, chemical, and mechanical properties has made it an indispensable material across nearly all industries since the 19th century. Aluminum is particularly valued for its low weight, high corrosion resistance, and excellent thermal and electrical conductivity. In addition, aluminum is easy to form, weld, and recycle, making it a future-proof and sustainable material.

- • low weight

- • high corrosion resistance

- • very good thermal and electrical conductivity

- • good formability and weldability

Beyond these core characteristics, aluminum offers remarkable adaptability: depending on the alloy composition and heat treatment, its mechanical properties can be specifically modified. Some alloys become significantly harder through heat treatment, while others provide excellent machinability or formability. This versatility allows aluminum to be tailored to specific technical requirements—whether for lightweight construction, series production, or the additive manufacturing of highly complex components.

Aluminum in additive manufacturing

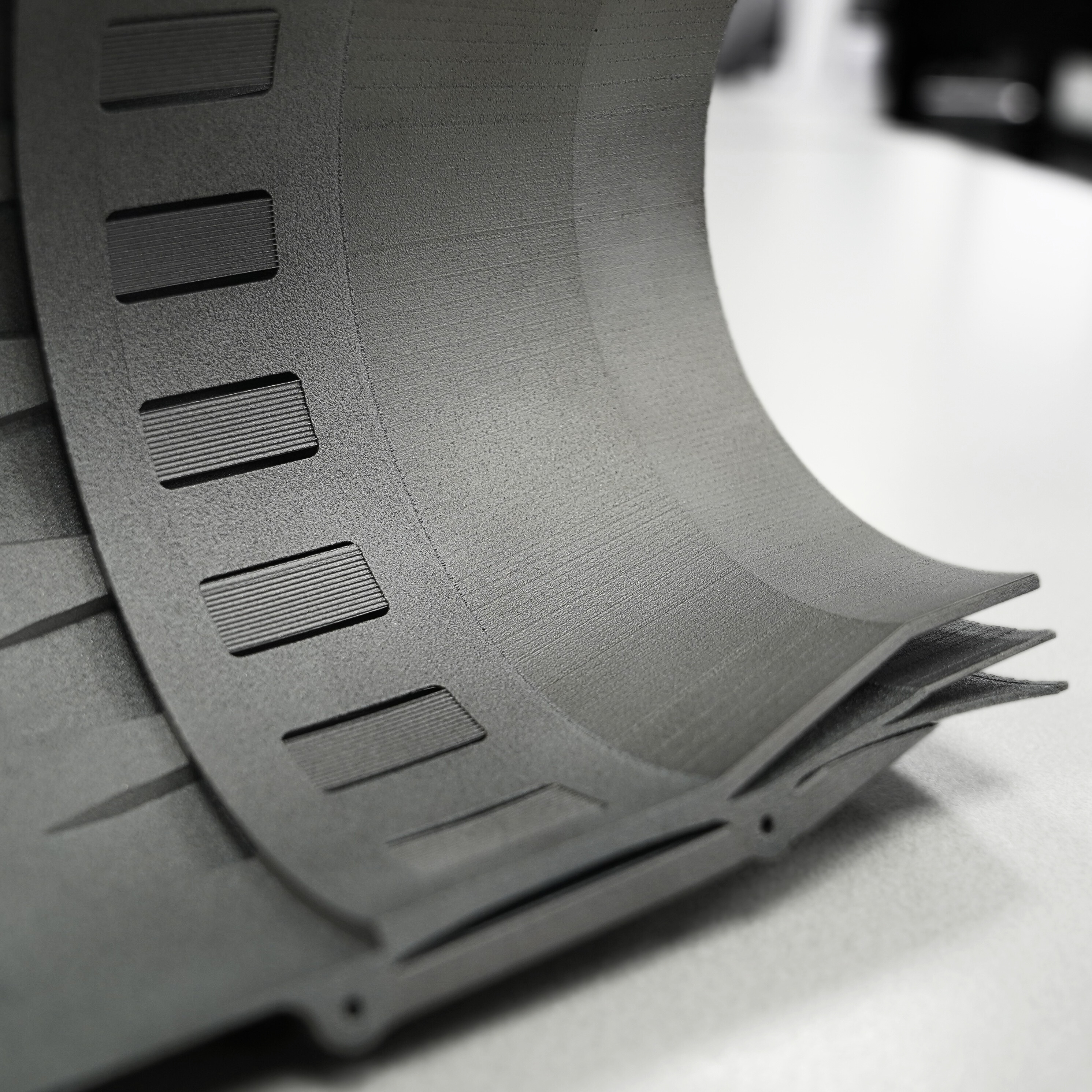

Aluminum is particularly well-suited for additive manufacturing, especially for Selective Laser Melting (SLM). This process enables the precise, fast, and mold‑free production of high‑strength metallic components.

Advantages of aluminum in the SLM process

- Weight reduction through optimized, bionically inspired structures

- Functional integration of multiple parts into a single component

- Fast and cost‑efficient prototype production

- Small to medium series production without tooling costs

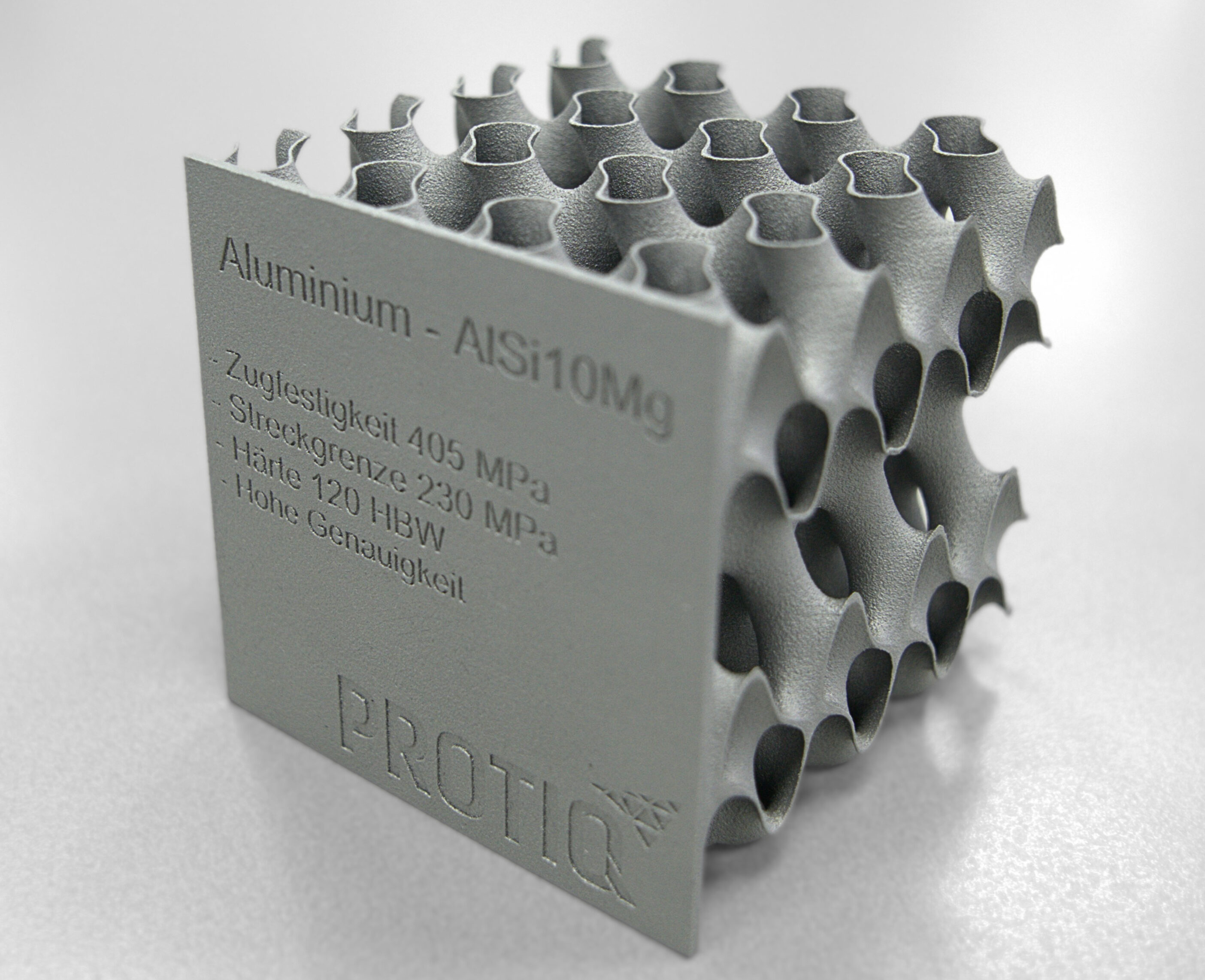

Material properties of Aluminum AlSi10Mg

Tensile strength

410 ± 20 MPa (as built);

340 ± 20 MPa (heat‑treated)

Elongation at break

6 ± 2% (as built);

7 ± 2% (heat‑treated)

Density

2.67 g/cm³

Hardness

120 HBW

Thermal conductivity

103 ± 5 W/(m*K)

Applications

Prototype manufacturing

Aluminum is frequently used in prototype development because it is lightweight, strong, and easy to machine. Ideal for functional prototypes, assembly tests, or experimental setups.

Series production

Alongside traditional manufacturing methods such as die casting or CNC milling, aluminum in 3D printing is also gaining importance for series production—particularly for:

- • small to medium batch sizes

- • components with complex geometries

- • integrated functions not manufacturable with conventional processes

Lightweight structures

Thanks to its excellent strength‑to‑weight ratio, aluminum is ideal for lightweight applications, such as:

- • aerospace

- • automotive engineering

- • mechanical engineering

- • robotics

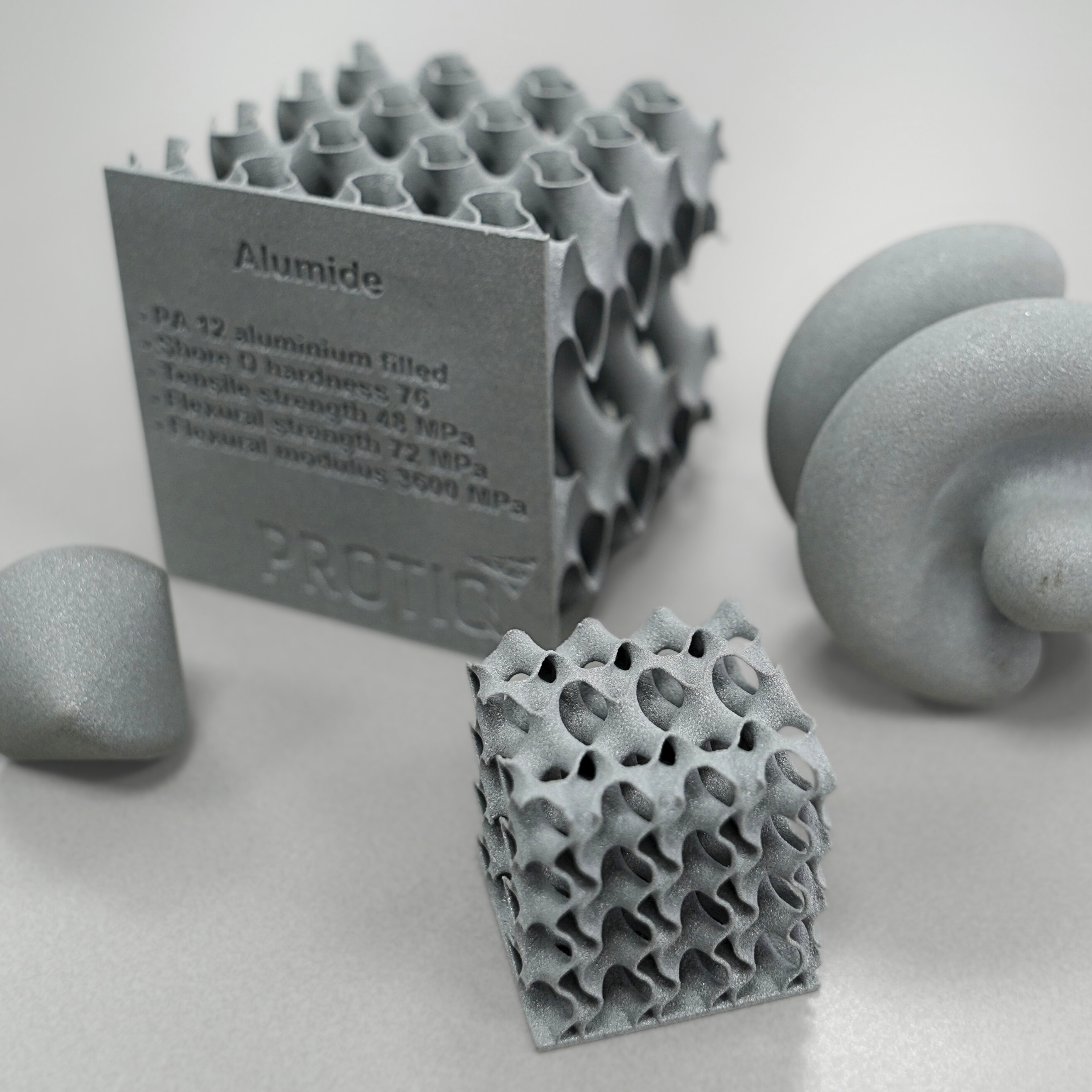

Aluminum combined with PA12 – Alumide

Alumide is a composite material made from PA12 and fine aluminum powder, processed using the Selective Laser Sintering (SLS) method. The combination of both materials gives the parts a gray metallic surface, increased stiffness, and a pleasantly firm feel, while maintaining the full design freedom of the SLS process. This enables the efficient and economical production of even complex geometries without support structures.

Properties

- high stiffness and dimensional stability

- improved thermal conductivity

- temperature‑resistant up to approx. 175 °C

- gray‑metallic, slightly grainy design surface

- excellent post‑processing (sanding, polishing, dyeing)

- complex geometries without support structures

- ideal for small series and design components

Do you have an idea or a specific project? Get in touch with us! We are happy to advise you.

Frequently Asked Questions about Aluminum in 3D Printing

Can aluminum 3D‑printed parts be post‑processed?

Yes. Aluminum parts can be mechanically post‑processed very well—e.g. by milling, drilling, or sanding. Surface finishing such as anodizing or polishing is also possible and enhances both appearance and functionality.

Can individual designs or special geometries be realized?

Absolutely. 3D printing offers maximum design freedom. You can upload your CAD data directly and manufacture precisely the geometries you need—from complex structures to custom‑designed components.

How does ordering via the PROTIQ Marketplace work?

It’s simple:

- • Upload CAD file

- • Select material & processing method

- • Receive instant price

- • Approve order

- • We begin production—fast, transparent, and reliable

Which CAD file formats are accepted?

We accept all common formats such as STEP, STL, and other industrial standards. This allows you to get started without conversion.

Are there minimum or maximum part sizes?

Yes. Maximum build volumes and technical limits depend on the selected process. During the ordering process, you will receive direct feedback on whether your part fits into the respective build chamber.

Are aluminum components suitable for series production?

Yes. Aluminum is excellent for small and medium series.

3D printing offers particular advantages here:

- • no tooling costs

- • flexible adjustments without retooling

- • economical even in small quantities

- • ideal complement to traditional die casting for iterative or custom designs

Deutsch

Deutsch English

English Italiano

Italiano