Additively manufactured heat exchangers

Maximum efficiency - minimum weight.

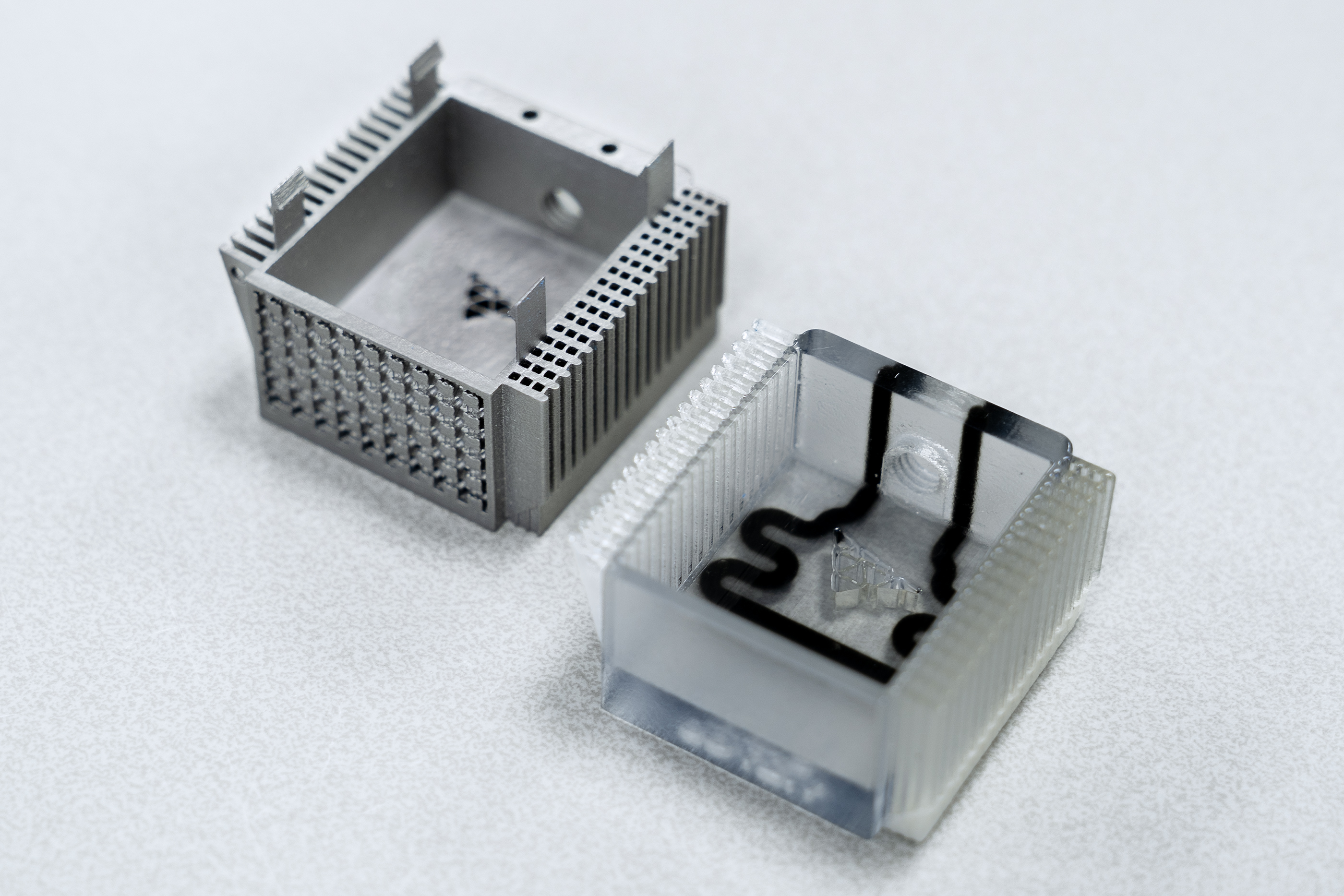

Additive manufacturing offers new possibilities in the production of heat exchangers, especially where conventional production processes reach their geometric or production technology limits. The layered structure allows complex cooling channels, organic structures and compact designs to be created, which enable optimized heat transfer.

What are heat exchangers?

Heat exchangers are indispensable components when it comes to transferring thermal energy between two media.

Whether in industry, air conditioning technology or the automotive sector - they ensure the efficient use of energy, regulate processes and enable the targeted cooling or heating of systems.

Conventional production - tried and tested, but limited

Traditionally, heat exchangers are made of metal - using processes such as milling, welding, soldering or bending. These methods offer solid results, but are often time-consuming and costly. Conventional manufacturing methods quickly reach their limits, especially when it comes to particularly complex internal structures that are crucial for optimum heat transfer.

Modern production technologies such as 3D printing open up new possibilities for producing heat exchangers with innovative, highly optimized geometries and further increasing efficiency.

Suitable materials for 3D-printed heat exchangers

The selection of a suitable metal depends heavily on the requirements for thermal conductivity, weight, machinability and corrosion behavior. Copper and aluminum are both suitable for additive manufacturing, but differ significantly in their physical properties.

Copper

Copper has a very high thermal conductivity and is therefore ideal for applications where maximum heat transfer is paramount.

Properties:

- Thermal conductivity: approx. 300-380W/mK

- Density: ~8.9g/cm³

- Electrical conductivity: very high

- Corrosion resistance: good, depending on the medium

- Strength: moderate, can be mechanically post-processed

Aluminium

Aluminum alloys offer a good balance of mechanical strength, weight and thermal conductivity and can be produced very well using additive manufacturing.

Properties:

- Thermal conductivity: approx. 120-150W/mK

- Density: ~2.7g/cm³

- Electrical conductivity: medium

- Corrosion resistance: very good

- Strength: good, especially after heat treatment

Typical areas of application

E-mobility

In electric vehicles, batteries, power electronics and electric motors need to be cooled efficiently. Additive manufacturing allows the production of application-specific heatsinks with integrated flow channels and optimized heat transfer with minimal installation space.

Industry and machine building

Reliable cooling solutions are crucial in industrial production, especially for high-performance machines, laser systems and converters. 3D-printed heat exchangers can be precisely adapted to process requirements and offer high thermal efficiency in a compact design.

ORDER 3D‑PRINTED HEAT EXCHANGERS NOW

Various copper and aluminium materials are now available on the PROTIQ Marketplace. Upload your 3D data on the homepage now. You will receive an instant quote for price and production time.

Medical technology

Small, powerful cooling units are required for imaging procedures, laser devices or portable diagnostic systems. Additive manufacturing also allows small quantities to be produced economically, often with function-integrated housings.

Power electronics

Power supplies, frequency converters and data centers require heat exchangers that are precisely matched to the electrical components. Additive manufacturing enables direct adaptation to the respective design and heat source.

What are the advantages of 3D-printed heat exchangers?

-

Higher thermal efficiency

Optimized geometries, e.g. complex channel systems, ensure improved heat transfer -

Design freedom without limits

Organic shapes, grid structures and internal cooling channels - can only be realized through additive manufacturing -

Compact design

Reduction in weight and volume without sacrificing performance - ideal for applications with tight installation spaces -

Faster product development

Short lead times from the idea to the functional prototype or series part

Do you have an idea or a specific project? Talk to us - we will be happy to advise you and show you how 3D printing can revolutionize heat exchangers.

Request your individual offer now >

Which materials are suitable for 3D printing heat exchangers?

We particularly recommend copper and aluminum. Copper offers excellent thermal conductivity, while aluminum offers a good balance of weight, strength and heat transfer - ideal for many industrial applications.

How does ordering via the PROTIQ Marketplace work?

It's simple: you upload your CAD file, select the material and process and receive a quote straight away. After approval, we start production - transparently, quickly and reliably.

Which CAD data formats are accepted?

We support common formats such as STEP, STL and others. Details can be found directly on the PROTIQ Marketplace or are available on request.

Are there minimum or maximum sizes for the components?

Yes, there are technical limits depending on the process and material. These are documented on our website - or you will receive an individual assessment after uploading your file.

Can the heat exchangers be reworked or coated?

Yes, we offer various post-processing options: from mechanical processing to surface finishing. This is how we ensure that your component is optimally prepared for use.

Deutsch

Deutsch English

English Italiano

Italiano