Simulation-based process analysis and optimization

Use our simulation and optimization service for your induction heating projects!

The heating behavior of inductors is crucial for the efficiency of your processes. However, until the perfect coil is achieved, conventional manufacturing processes usually require many geometries to be produced and tested in real heating trials. This is costly and time-consuming. With the PROTIQ service of a computer-aided simulation of your processes you will get the ideal inductor for your application. We support you in analyzing the heating process, identifying improvement potentials and optimizing your inductors.

With simulation methods from PROTIQ to the perfect inductor

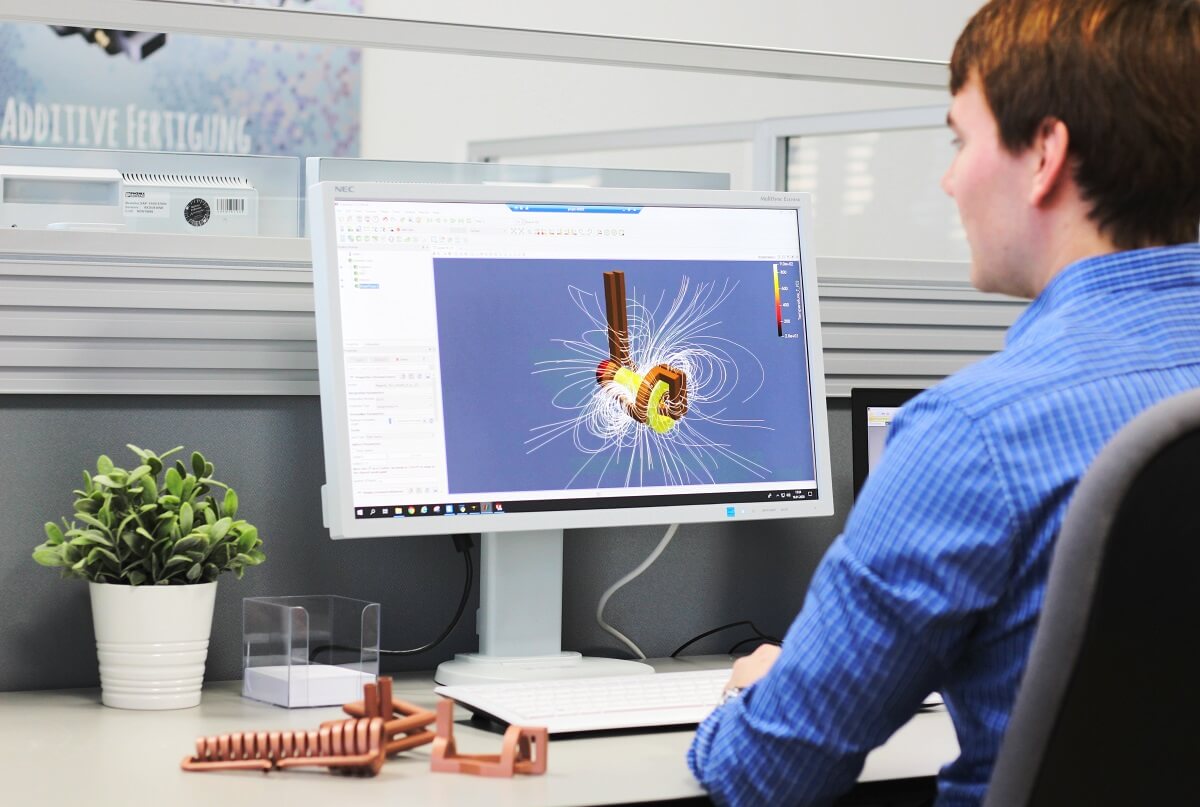

PROTIQ offers its customers a special service for the analysis and optimization of copper coils for inductive heating: Using numerical simulation methods, the behavior of the coils in the process is visualized and an optimized inductor geometry is determined. The components are then produced quickly and cost-effectively using a 3D printing process, from highly electrically conductive pure copper.

You gain valuable insight into otherwise invisible process influences as well as their interactions. This information about the heating process can be used directly to develop and improve new processes.

PROTIQ's optimized and additively manufactured inductors impress with their fast and precise heating behavior. Thus, more accurate hardness patterns can be set on the component and lower cycle times in series production can be achieved.

How does PROTIQ's optimization service work?

After you have provided us with your data, the first step is to map the induction heating process of your application in a simulation model. In addition to the geometry of the inductor and the component to be heated, this model also contains information about the existing boundary conditions and process parameters. On this basis, the thermal heating behavior of the component and the electro-magnetic properties of the coil can then be mapped and investigated.

The results obtained from this allow a much more detailed analysis of the process behavior than real heating tests. As part of the simulation, the heating inside the component can also be examined, for example, or the magnetic field that builds up can be visualized. In this way, PROTIQ analyzes and optimizes existing inductors or determines the parameters for new heating processes.

In this way, you receive high-quality copper coils that are ideally suited to your applications. We would be pleased to provide you with an individual offer!

This is how you benefit from our simulation service:

- Valuable analysis of process behavior

- Visualization and evaluation of the simulation shows optimization potentials

- Coils with ideal properties for your individual processes

- Time savings in development

- Reduced costs in development

- Fewer real tests with experimental geometries necessary

- High-precision inductors, 3D-printed from pure copper

- Manufacturing of your inductors within a few days

Benefits of additive manufacturing for your processes

3D printing has long been accepted as a manufacturing process for induction coils. The advantages over conventional production methods are numerous: by relying on computer-aided numerical simulations, such as those offered by PROTIQ, expensive testing as well as precious development time can be reduced to a significant degree. In addition, additive manufacturing can easily produce very complex geometries where other manufacturing processes reach their limits. Individual profile shapes and minimal bending radii are no obstacle, so that innovative inductor geometries with optimized magnetic field guidance and improved process properties can be developed. Manufactured by 3D printing within a few days, PROTIQ is made of 100% pure copper.

You want to get more out of your heating processes?

Take advantage of PROTIQ's simulation service! Our experts will be happy to advise you and work with you to find the optimal solution for your heating process.

Deutsch

Deutsch English

English